What is the difference between a self-priming centrifugal pump and a self-priming pump?

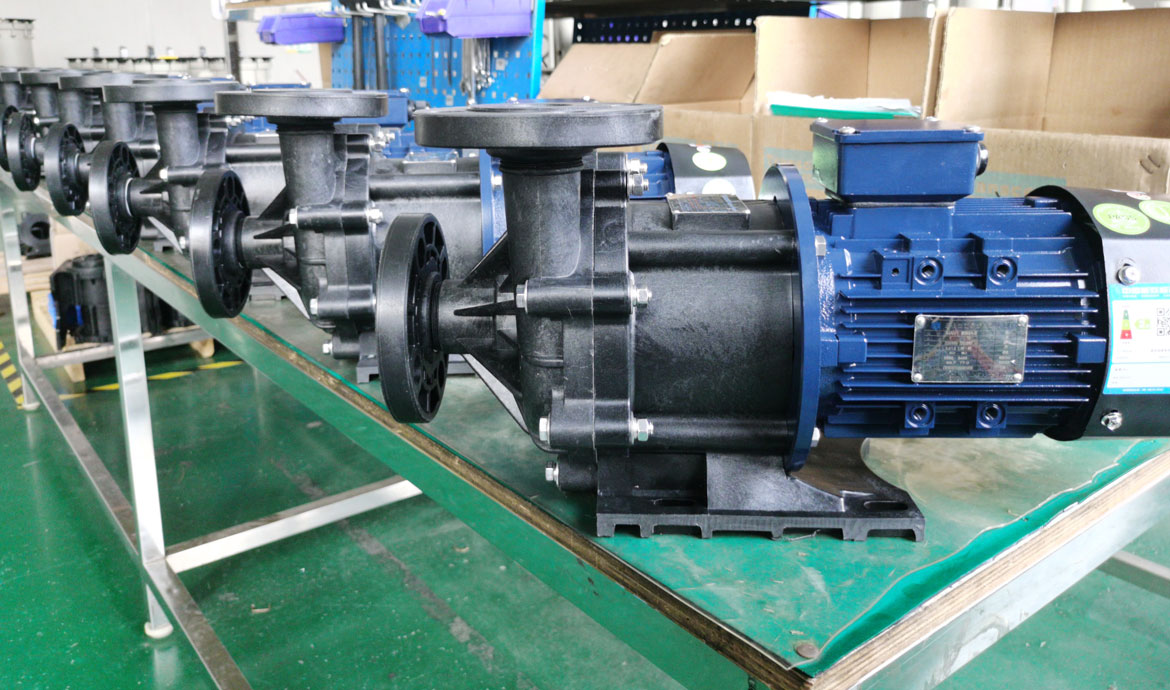

The self-priming pump is a self-priming centrifugal pump, which has the advantages of compact structure, easy operation, smooth operation, easy maintenance, high efficiency, long life and strong self-priming ability. There is no need to install a bottom valve in the pipeline, and it is only necessary to ensure that there is a quantitative priming liquid stored in the pump before work. Different liquids can be self-priming pumps with different materials.

Self-priming pumps are self-priming pumps that are started without the need to fill the suction pipe with water (but there must be enough water in the pump body) and have the function of automatically excluding the gas in the suction pipe and entering normal work after a short period of operation. Self-priming pumps must be filled with enough water before the initial start, and later on the pump will be started again by the water left in the pump body to enter normal work.

Differences between self-priming centrifugal pumps and centrifugal pumps

1) Before starting, the self-priming centrifugal pump must be filled with a certain amount of starting circulating water when starting for the first time, while the centrifugal pump needs to be filled with water in the inlet pipe and in the pump at the same time when starting each time, or the inlet pipe can be pumped with an auxiliary device.

2) On the device, the self-priming centrifugal pump is only equipped with a strainer at the lower end of the inlet pipe without a bottom valve; whereas the centrifugal pump must be equipped with a bottom valve at the lower end of the inlet pipe or with a pumping device at the outlet.

3) When operating, the same performance parameters of the pump, generally self-priming centrifugal pump than the centrifugal pump efficiency is lower, cavitation performance is poor.

The gas-liquid mixed self-priming centrifugal pump must complete three processes when working: the gas inside the impeller is brought out of the impeller reciprocally; the gas-liquid separation is carried out effectively; the separated water is continuously returned to the impeller to work again.

According to the different parts of the water and gas mixing, gas-liquid mixed self-priming centrifugal pump is divided into internal mixing and external mixing type. The water in the gas-liquid separation chamber flows back to the inlet of the impeller, and the gas and water are mixed at the inlet of the impeller, which is called the internal mixed self-priming centrifugal pump. The water in the gas-liquid separation chamber flows back to the impeller outlet, and the gas and water are mixed at the outer edge of the impeller, which is called the external mixed self-priming centrifugal pump.