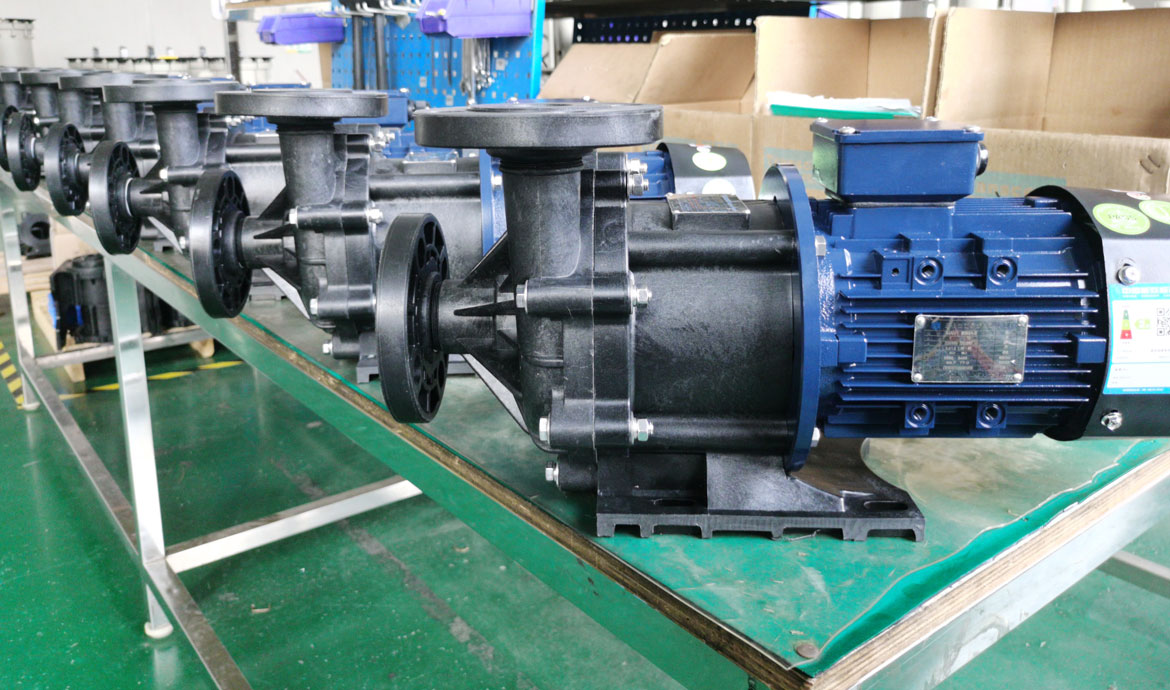

Three moves to teach you to extend the service life of magnetic pumps

In order to further extend the service life of the magnetic pump, it is recommended that more people understand the precautions in the use process.

1, conventional models of magnetic pumps use temperature in -20 ℃ to 100 ℃, motor temperature rise requirements can not exceed 75 ℃, if idling or other unexpected working conditions lead to temperature exceeds the standard, may cause the magnetic pump demagnetization, so we should pay strict attention to the use of the environment and the pump body temperature conditions, if there is a demand for transportation of high temperature media, you can contact the manufacturer in advance to customize high temperature resistant pump type.

2, when carrying out installation, need to set separate support for the pipeline, not directly apply the weight of the pipeline on the pump 0 body, try to maintain horizontal installation, such as special requirements must be installed vertically, to keep the motor facing up.

3、Check the flexibility of the motor fan before starting the machine, there should be no jamming or strange noise, and check that the fasteners are not loose.

After starting the machine, slowly open the discharge valve, and then adjust the discharge valve opening degree according to the need after the normal and stable operation parameters of the pump.

After the above content, I believe you have an intuitive understanding of the magnetic pump maintenance cycle, in use in strict accordance with the cycle of maintenance and repair, while focusing on the daily use, can significantly extend the service life of the pump.