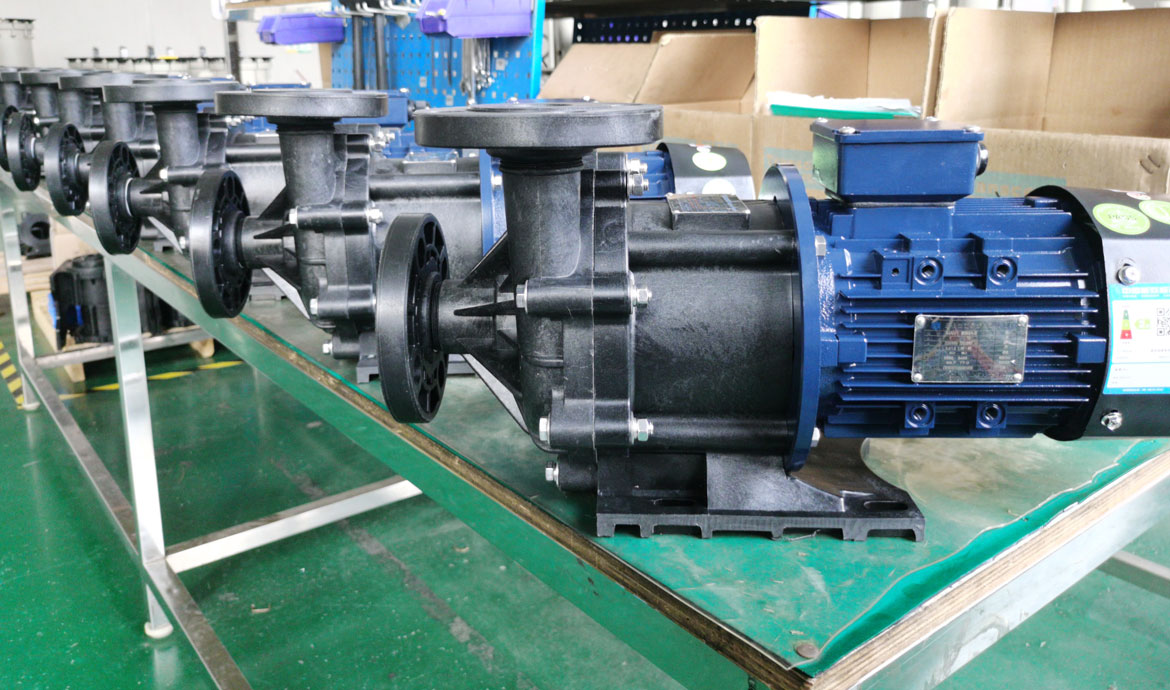

How to solve vibration problems with horizontal magnetic pumps?

1、The pump shaft and the motor shaft of the magnetic pump are not centred

The magnetic pump is usually connected by a shaft coupling, because the motor and the pump are connected by a shaft coupling, the motor and the pump head are shifted during transportation or installation, resulting in the motor shaft and the pump shaft not being on the same level, and the loss of equilibrium will cause a strange noise and vibration. Be sure to correct the coupling, so that the motor shaft and pump shaft in the same horizontal line, so as to get rid of this situation, can also be changed to no coupling magnetic pump.

2、The quality of the magnetic pump itself

As the market is now chaotic, and the establishment of units at a lower cost, resulting in a large number of shell units without manufacturing, as well as some products manufacturing technology is not up to standard small enterprises flood the market. The quality and technology of some magnetic pumps cannot be effectively maintained. There will be, for example, unbalanced quality of motor and chemical pump running parts, shoddy workmanship, poor installation quality, uneven axis of the unit, swing beyond the value, poor mechanical strength and stiffness of parts and other product quality failures, which will lead to unstable operation of the magnetic pump products, resulting in vibration when the magnetic pump is in operation. So the user must choose the regular manufacturer when purchasing.

3, whether the magnetic pump motor is defective

In the construction of magnetic pump products, the motor is an indispensable part of the unit, if the internal magnetic force of the motor is unbalanced and other electrical vapor system disorders, it is likely to cause the whole unit to vibrate and produce noise. For example, in the operation of an asynchronous motor, the radial alternating magnetic pull between the stator and rotor is generated by the interaction of the stator and rotor teeth harmonic flux. For example, when a large synchronous motor is in operation, the stator-rotor magnetic centre is not the same or the difference in the vapour gap in each direction exceeds the deviation value, which may cause the motor to vibrate periodically and make noise.

Therefore, the options and quality of the motor also affect the vibration of the magnetic pump operation.

4, magnetic pump conveying media reasons

The operation of the magnetic pump and water and other liquids are closely related, so the natural transmission of the liquid will also affect the operation of the magnetic pump. For example, the chemical pump inlet flow rate and pressure distribution is not uniform, the pump import and export operation medium pressure pulsation, medium around the flow, partial flow and off flow, non-quota working conditions and various factors caused by chemical pump cavitation, etc., will cause the magnetic pump in the operation of vibration.

5, magnetic pump flow beyond the application of cavitation

Cavitation is the magnetic pump operation of the noise, vibration and efficiency of the primary factors, cavitation may also cause damage to part of the magnetic pump surface, when the import pipeline is too thin or too long, the export pump flow exceeds the import pump flow, the pump will occur cavitation, cavitation occurs, the noise becomes significantly larger, the pump cavity will produce more bubbles, bubbles with the impeller operation, hit the pump cavity parts, will lead to serious damage to the pump Serious damage will be caused to the pump, this condition is called cavitation condition. Methods to reduce cavitation: shorten the length of the inlet pipeline, increase the diameter of the inlet pipe, off less than the export valve, etc. can effectively reduce cavitation.

6、Is there any damage to the magnetic pump?

In the magnetic pump through a long period of operation, the product parts wear bad, resulting in chemical pump magnetic pump can not be correct operation and operation, often occurring vibration conditions, it is necessary to check the magnetic pump, is there parts damage caused by the product occurred obstacles. Magnetic pump vibration, first of all, we must first stop running, cautiously check the obstacle factors, in accordance with the reality of the situation to overhaul solutions. If there is no professional staff, please contact the manufacturer to provide technical support.

7、Magnetic pump tensioning bolt is loose

Long-term application of magnetic pump may appear foundation bolts or magnetic pump motor bolts pump body bolts slack condition, so the application such as the discovery of bolts slack condition need to tighten good.

Previous: Where are PVDF magnetic pumps used?

Next: Uses of chemical pumps